28

Dec

How to control the rust removal effect of sandblasting machine

How to control the rust removal effect of sandblasting machine

When using a sandblasting machine to derust the workpiece, how to control the sandblasting machine so that its operation can reach the function we need? 1. Early control When we start sandblasting, we will refer to the rules of "Steel Surface Rust Grade and Derust Grade before...

27

Dec

The detailed structure of the freezing sandblasting machine is introduced

The detailed structure of the freezing sandblasting machine is introduced

The freezing sandblasting machine is mainly divided into the main structure, the high-speed motor and the ejection wheel, and the necessary auxiliary system. 1, host structure mainly includes: feeding system, circulation system, temperature control system, and electronic control system. 2,...

26

Dec

What are the ways to calculate the air volume in the sandblasting room

What are the ways to calculate the air volume in the sandblasting room

For the sandblasting room, there are several ways to calculate the air volume, the common ones are the number of air changes and the calculation of the cross-sectional area. (1) The number of air changes, that is to say the volume of the entire blasting room, we estimate according to the...

25

Dec

Why can water sandblasting machine replace high-pressure water cleaning equipment

Why can water sandblasting machine replace high-pressure water cleaning equipment

water sand blasting machine has been widely used, replacing the original backward sand blasting and replacing the high-pressure water cleaning equipment. The combined hydraulic cleaning effect is higher, there is no damage to the surface, and the equipment is very easy to operate. The water...

24

Dec

Four advantages of bag dust collector for sandblasting machine

Four advantages of bag dust collector for sandblasting machine

1. Dust removal efficiency of bag filter of sandblasting machine The dust removal efficiency mainly depends on the type of filter material. If the polyester needle felt filter material is used, the dust removal efficiency can be guaranteed above 99%. 2. Pressure loss of bag filter of...

23

Dec

Classification of sandblasting room

Classification of sandblasting room

The sandblasting room is mainly divided into two categories based on the abrasive recovery method: One type is wind (gas) force recycling type sandblasting room: Wind (pneumatic) recycling sand blasting room uses the negative pressure generated by the suction of the fan to recover the abrasives,...

22

Dec

Points for attention in the selection of sandblasting room

Points for attention in the selection of sandblasting room

1. When the customer selects the sandblasting room, the customer combines its own actual situation and the guidance of our company's technical personnel, through comprehensive analysis and comparison, selects the abrasive recycling method, so as to determine the type of sandblasting room to...

21

Dec

Suggestions on the use and management of sandblasting room equipment

Suggestions on the use and management of sandblasting room equipment

The sandblasting room is a comprehensive equipment involving machinery, electricity, lighting, PLC, pneumatic, fan, compressed air, dust removal, dehumidification, etc. It requires the equipment management department to arrange special personnel for key management. However, the reality is that...

20

Dec

Classification of recycling sandblasting rooms in Qingdao Wozhou

Classification of recycling sandblasting rooms in Qingdao Wozhou

Qingdao Wozhou has produced various types of sand blasting rooms for many years. Recycling sand blasting rooms are also one of them. At present, it is mainly divided into two categories based on abrasive recovery methods. One is the wind (gas) force recycling sand blasting room. The other is a...

19

Dec

Five key control points in the working process of sandblasting room

Five key control points in the working process of sandblasting room

The sandblasting room can be roughly divided into five steps in the working process, mainly including: pre-control, abrasive control, tool control, condition control and quality control. 1. Early control Before sandblasting, the surface of the workpiece must be carefully inspected to remove...

18

Dec

Design basis for large-scale sandblasting room in work

Design basis for large-scale sandblasting room in work

With the rapid development of China's steel structure, there is an increasing demand for large-scale sandblasting rooms in large-scale steel structure projects, and the design basis of large-scale sandblasting rooms in the work is particularly important. The design of the sandblasting room...

17

Dec

Process issues that need to be paid attention to when building a sandblasting room

Process issues that need to be paid attention to when building a sandblasting room

When building a sandblasting room, it is necessary to pay more attention to the process of the sandblasting room. With the continuous progress of society, people have higher and higher requirements for product coating, and the choice of sandblasting process of sandblasting machine manufacturers...

16

Dec

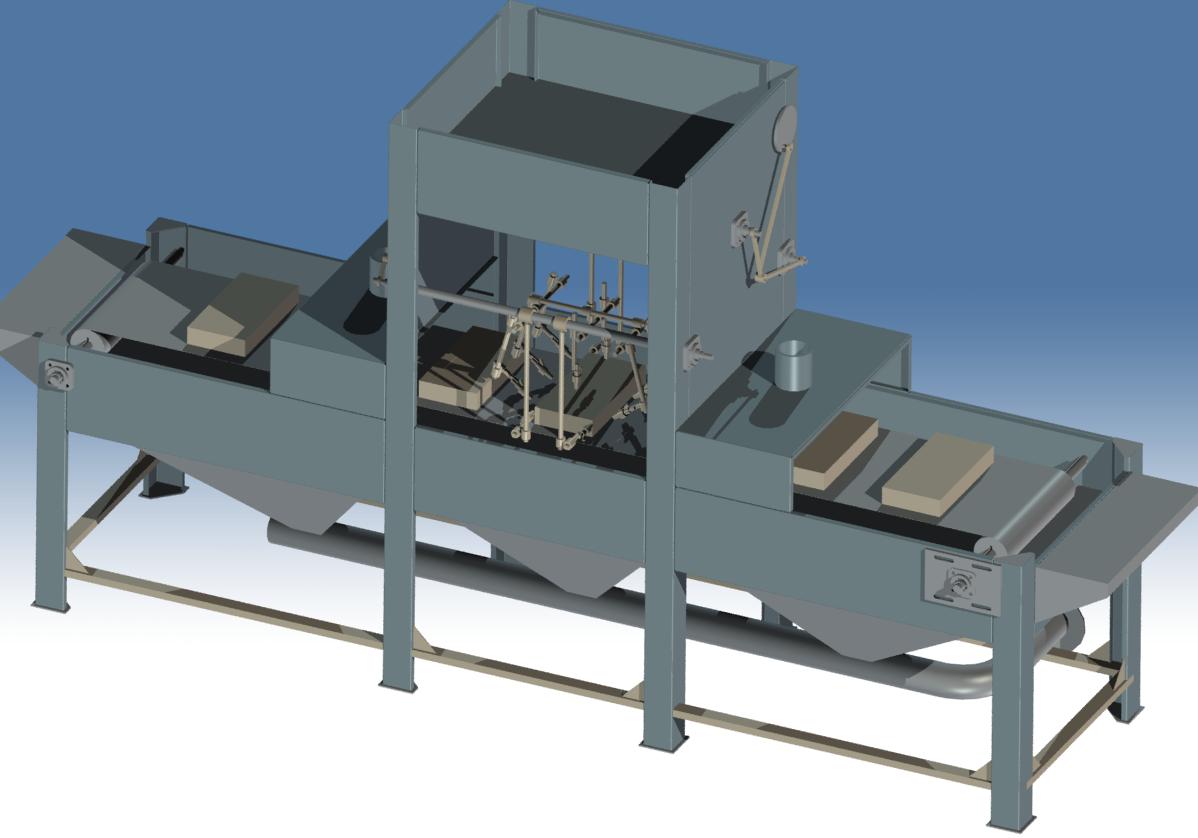

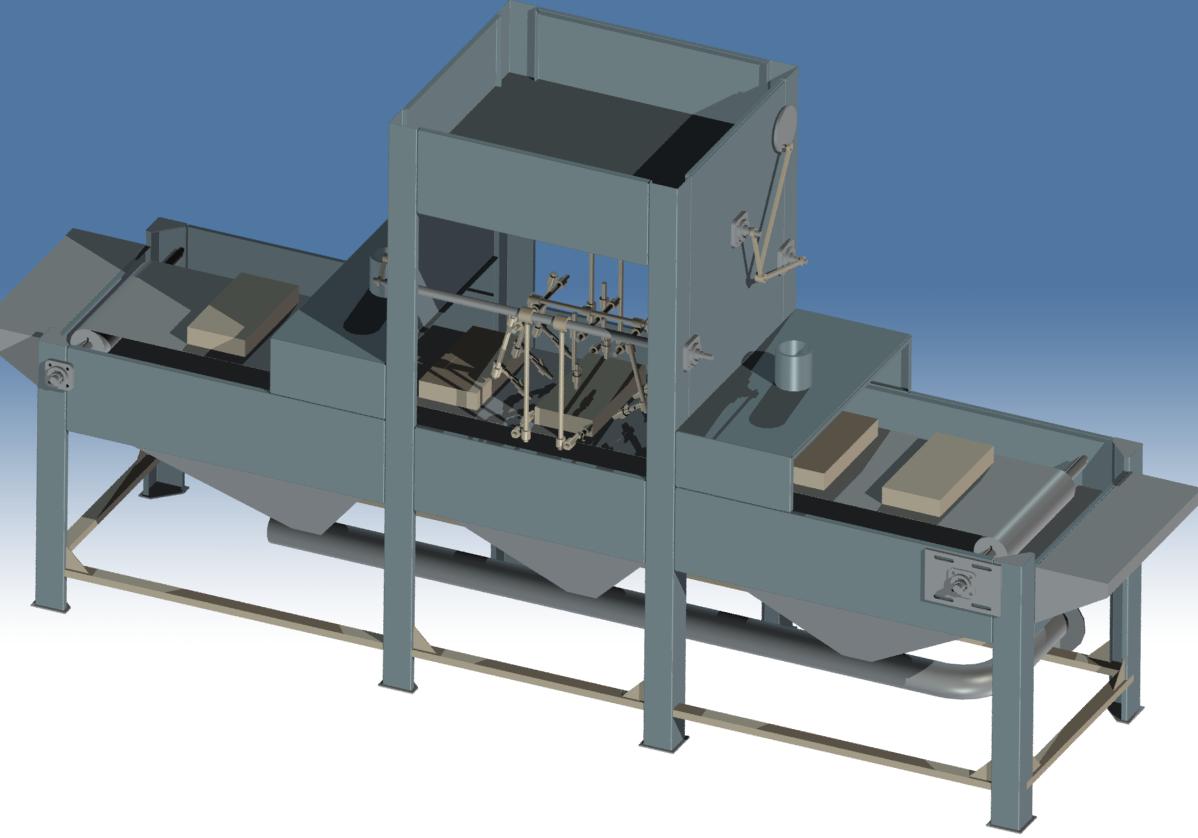

Four classifications of automatic sandblasting machine

Four classifications of automatic sandblasting machine

1 Conveying automatic sandblasting machine Conveyor automatic sand blasting machine is also called flat automatic sand blasting machine and assembly line sand blasting machine. It is a high-volume automatic sandblasting machine. The products that need sandblasting are placed on the left side....

15

Dec

The main points of building a sandblasting room

The main points of building a sandblasting room

With the increasing demand for spraying, sandblasting room manufacturers have become the choice of many customers with spraying needs. Sandblasting rooms can not only increase coating adhesion, improve decoration, and enhance product corrosion resistance; it can also eliminate metal surface...

14

Dec

What requirements need to be met when designing a sandblasting room

What requirements need to be met when designing a sandblasting room

When designing the sandblasting room, it is necessary to consider the requirements of current users and various shipbuilding codes, as well as the new coating requirements of IMO codes. Mainly to meet these requirements: ① Carry out painting operations normally around the clock; ② The process...

13

Dec

What are the requirements for the electrical control system in the sandblasting room

What are the requirements for the electrical control system in the sandblasting room

The electrical control system in the blasting room can realize centralized control of the cleaning room of the blasting room. This system takes the programmable logic controller (PLC) as the core, adopts high-quality electrical components, has many advantages such as reliable work, high degree...

12

Dec

The difference between the outer circulation and the inner circulation of the water blasting machine

The difference between the outer circulation and the inner circulation of the water blasting machine

Water blasting machine is a kind of sand blasting machine, which is widely used. According to the circulation mode, water blasting machine can be divided into external circulating water blasting machine and internal circulating water blasting machine. The main feature of the external circulating...

11

Dec

The application value of box sandblasting machine in life

The application value of box sandblasting machine in life

The box-type sandblasting machine actually uses compressed air as the kinetic energy to create a reliable radiation beam, and sprays the spray material to the surface of the part to be processed, so that changes are found on the surface of the part. The surface layer of the part is caused by the...

10

Dec

What is the difference between sandblasting machine and shot blasting machine

What is the difference between sandblasting machine and shot blasting machine

Many people often mix the sand blasting machine with the shot blasting machine. When in use, there is a certain difference between the sand blasting machine and the shot blasting machine. The sandblasting machine uses compressed air as the power, and the compressed air brings sand (emery,...

09

Dec

Analysis of common failures of suction sandblasting machine

Analysis of common failures of suction sandblasting machine

1. The sand blasting gun only vents air but not sand; analysis of the reason: ①The sand blasting port is plugged; ②The air compressor has large water vapor and the sand outlet is wet; Remedy: ①Remove the sand outlet and clean the debris Object; ②Large the sand valve; 2. Gradually reduce the...