19

Jun

1.4mm cast steel grit process

1.4mm cast steel grit process

Smelting: Use intermediate frequency furnace for smelting, so that high-quality molten steel can be obtained and the quality of steel shot can be greatly improved; Refining: Use a refining furnace to refine the molten steel to improve the purity of the molten steel, so that the steel shot can...

17

Jun

1.4mm cast steel grit has outstanding advantages

1.4mm cast steel grit has outstanding advantages

· Use intermediate frequency furnace for smelting to ensure high-quality molten steel; · Use a refining furnace for molten steel refining; · Use high-speed centrifugal casting to form; · Effectively separate hollow and heterogeneous defective particles to provide steel shot density; · Use...

14

Jun

1.2mm cast steel grit process

1.2mm cast steel grit process

Smelting: use intermediate frequency furnace for smelting, so that high-quality molten steel can be obtained and the quality of steel shot can be greatly improved; Refining: Use a refining furnace to refine the molten steel to improve the purity of the molten steel, so that the steel shot can...

13

Jun

1.2mm cast steel grit has outstanding advantages

1.2mm cast steel grit has outstanding advantages

· Use intermediate frequency furnace for smelting to ensure high-quality molten steel; · Use a refining furnace for molten steel refining; · Use high-speed centrifugal casting to form; · Effective separation of hollow and heterogeneous defect particles to provide steel shot density; · Use...

11

Jun

1.0mm cast steel grit process

1.0mm cast steel grit process

Smelting: use intermediate frequency furnace for smelting, so that high-quality molten steel can be obtained and the quality of steel shot can be greatly improved; Refining: Use a refining furnace to refine the molten steel to improve the purity of the molten steel, so that the steel shot can...

10

Jun

1.0mm cast steel grit has outstanding advantages

1.0mm cast steel grit has outstanding advantages

· Use intermediate frequency furnace for smelting to ensure high-quality molten steel; · Use a refining furnace for molten steel refining; · Use high-speed centrifugal casting to form; · Effective separation of hollow and heterogeneous defect particles to provide steel shot density; · Use...

08

Jun

Outstanding advantages of 0.7mm cast steel grit

Outstanding advantages of 0.7mm cast steel grit

Smelting: use intermediate frequency furnace for smelting, so that high-quality molten steel can be obtained and the quality of steel shot can be greatly improved; Refining: Use a refining furnace to refine the molten steel to improve the purity of the molten steel, so that the steel shot can...

07

Jun

Outstanding advantages of 1.5mm strengthened steel wire cut shot

Outstanding advantages of 1.5mm strengthened steel wire cut shot

· The service life is 3-4 times that of ordinary steel shot; · Choose Baosteel and Shagang new steel wires as raw materials; · Adopt advanced German cutting technology; · According to German VDFI8001/2009 and American SAEJ441/AMS2431 standards; · Strong toughness, not easy to break, and strong...

05

Jun

0.5mm cast steel grit process

0.5mm cast steel grit process

Smelting: use intermediate frequency furnace for smelting, so that high-quality molten steel can be obtained and the quality of steel shot can be greatly improved; Refining: Use a refining furnace to refine the molten steel to improve the purity of the molten steel, so that the steel shot can...

03

Jun

0.3mm cast steel grit process

0.3mm cast steel grit process

Smelting: use intermediate frequency furnace for smelting, so that high-quality molten steel can be obtained and the quality of steel shot can be greatly improved; Refining: Use a refining furnace to refine the molten steel to improve the purity of the molten steel, so that the steel shot can...

01

Jun

0.2mm cast steel grit process

0.2mm cast steel grit process

Smelting: use intermediate frequency furnace for smelting, so that high-quality molten steel can be obtained and the quality of steel shot can be greatly improved; Refining: Use a refining furnace to refine the molten steel to improve the purity of the molten steel, so that the steel shot can...

30

May

Working principle of dry filter cartridge dust collector

Working principle of dry filter cartridge dust collector

Dry filter cartridge dust collector refers to the method of blowing compressed air to remove the dust attached to the filter medium (cloth bag or filter cartridge); according to the size of the dust collector, there may be several sets of pulse valves, which are controlled by a pulse controller...

29

May

Working principle of pulse dust collector

Working principle of pulse dust collector

Pulse dust collector refers to the method of blowing compressed air to remove the dust attached to the filter medium (cloth bag or filter cartridge); according to the size of the dust collector, there may be several sets of pulse valves, which are controlled by a pulse controller or PLC, each...

27

May

Working principle of filter cartridge dust collector

Working principle of filter cartridge dust collector

Filter cartridge dust collector refers to the method of blowing compressed air to remove the dust attached to the filter medium (cloth bag or filter cartridge); according to the size of the dust collector, there may be several sets of pulse valves, which are controlled by a pulse controller or...

25

May

Working principle of wet dust collector (standard version)

Working principle of wet dust collector (standard version)

The dust-containing fan is used to suck the dust-containing air into the air inlet of the wet dust removal system, and the large particles of dust are preliminarily filtered and separated using the Venturi principle and star unloader, and discharged to the pre-dust box of the system. The...

22

May

The working principle of the wet dust collector upgrade (explosion-proof)

The working principle of the wet dust collector upgrade (explosion-proof)

The dust-containing fan is used to suck the dust-containing air into the air inlet of the wet dust removal system, and the large particles of dust are preliminarily filtered and separated using the Venturi principle and star unloader, and discharged to the pre-dust box of the system. The...

20

May

Working principle of Venturi wet dust collector (explosion-proof version)

Working principle of Venturi wet dust collector (explosion-proof version)

The Venturi wet dust collector (explosion-proof version) is used to suck the dust-containing air into the air inlet of the wet dust removal system, and the large particles of dust are preliminarily filtered and separated using the Venturi principle and star unloader, and discharged to the...

18

May

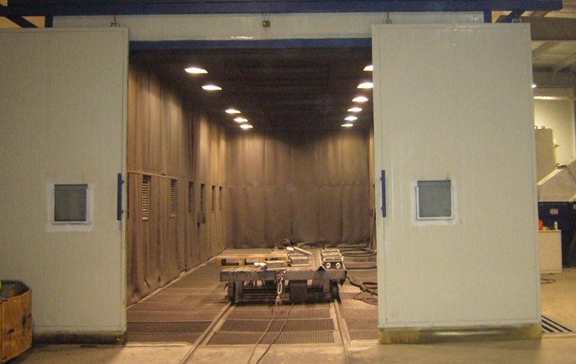

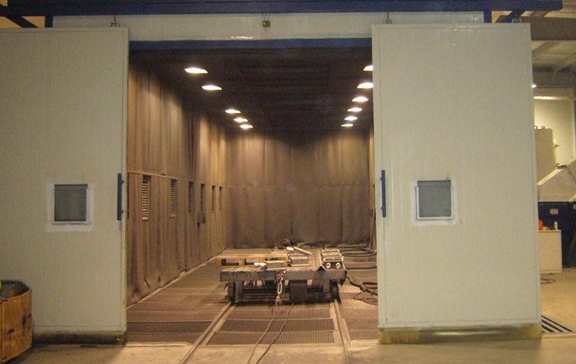

Working principle of semi-automatic sandblasting house

Working principle of semi-automatic sandblasting house

Semi-automatic sandblasting house is also called shot blasting room and sand blasting room. It is suitable for surface cleaning and derusting of some large workpieces, and increases the adhesion effect between the workpiece and the coating. Before sand blasting, the workpiece is sent into the...

15

May

Working principle of semi-automatic sandblasting room

Working principle of semi-automatic sandblasting room

Semi-automatic sand blasting room is also called shot blasting room and sand blasting room. It is suitable for surface cleaning and rust removal of some large workpieces to increase the effect of adhesion between the workpiece and the coating; before the sand blasting operation, the workpiece is...

14

May

Working principle of auto sandblasted room

Working principle of auto sandblasted room

The auto sandblasted room is also called shot blasting room and sand blasting room. It is suitable for surface cleaning and rust removal of some large workpieces, and increases the adhesion effect between the workpiece and the coating; before the sand blasting operation, the workpiece is sent to...