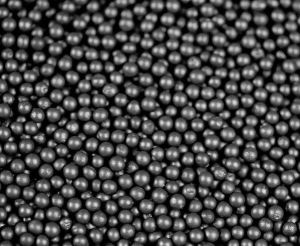

Shot blasting abrasive cast steel shots are widely used for descaling and descaling treatments before painting steel workpieces, in which case centrifugal shot blasting equipment is often used.

Silicon carbide is made of quartz sand, petroleum coke (or coal coke), wood chips (need to add table salt when producing green silicon carbide) and other raw materials through high-temperature smelting in a resistance furnace.

Iron steel sand is a new type of wear-resistant material in recent decades, basically made of iron steel from natural iron ore, mainly iron oxide.

Iron steel sand is a new type of wear-resistant material in recent decades, basically made of iron steel from natural iron ore, mainly iron oxide.

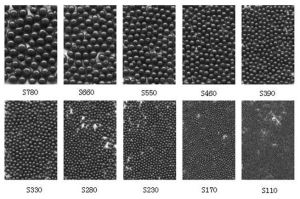

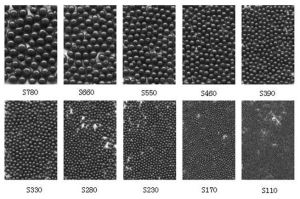

Simple process control. More than 90% of the steel shots are round, and the shaped steel shots cannot exceed 10%.

Silicon carbide is made of quartz sand, petroleum coke (or coal coke), wood chips (need to add table salt when producing green silicon carbide) and other raw materials through high-temperature smelting in a resistance furnace.

Steel wire shot blasting cleaning: shot blasting cleaning, shot blasting cleaning, die casting cleaning, casting blasting cleaning, forging shot blasting cleaning, forging shot blasting casting, sand cleaning steel plate cleaning, steel cleaning, steel plate cleaning, H-beam...

Iron steel sand is a new type of wear-resistant material in recent decades, basically made of iron steel from natural iron ore, mainly iron oxide.

The alloy cast steel shot has the advantages of fast cleaning speed, long service life and low consumption.

The alloy cast steel shot has the advantages of fast cleaning speed, long service life and low consumption.

The alloy cast steel shot has the advantages of fast cleaning speed, long service life and low consumption.

Simple process control. More than 90% of the steel shots are round, and the shaped steel shots cannot exceed 10%.

Sep 01, 2020

Aug 31, 2020