Description

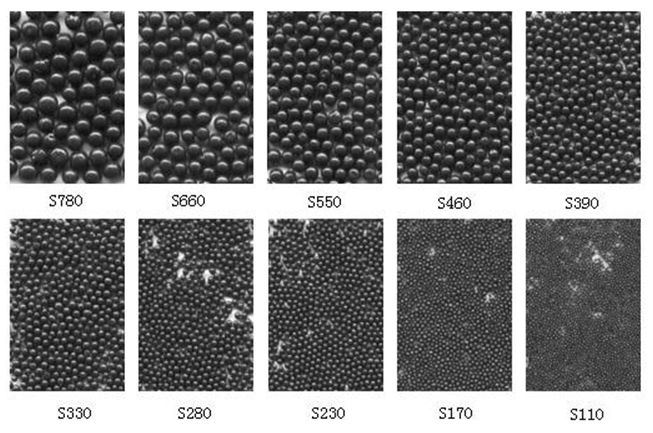

Simple process control. More than 90% of the steel shots are round, and the shaped steel shots cannot exceed 10%.

Share:

High carbon cast steel shot is the most widely used metal abrasive for shot blasting cleaning and strengthening, suitable for metal surfaces in industries such as automobiles, shipbuilding, railway locomotives, aircraft, bridges, containers, machinery manufacturing, steel structures, pressure vessels, stone, etc. Shot peening and strengthening.

High carbon cast steel shot advantage:

1)Good liquidity. Because it is composed of spheres with a certain size range, the fluidity is better than steel grit or steel wire shot.

2) Simple process control. More than 90% of the steel shots are round, and the shaped steel shots cannot exceed 10%. There are few steel shots with sharp corners (the hardness of the broken steel shots is relatively low during use), so there is no need to consider the single input when the supplement is too large. The problem of steel plate surface damage.

3) No local damage to the strip surface. Without controlling the mixing ratio of the pellet size, even if the new steel pellets are put in a large amount at a time, they will not cause local deep spots on the surface of the steel plate.

4) Less damage to the blade and guard plate of the shot blasting machine. The hardness of high carbon cast steel shot is relatively small, and the hardness of the sharp corners formed after the steel shot is broken during the shot process is relatively low. The loss is relatively small.