Description

The inlet air volume of the cyclone dust collector is Q=3600AVT, where, Q--the inlet air volume of the cyclone dust collector, m3/h; A — the inlet cross-sectional area of the cyclone dust collector, m2. Therefore, when the structure is fixed (R is unchanged, A is unchanged), and the dust is the...

Share:

The inlet air volume of the cyclone dust collector is Q=3600AVT, where, Q--the inlet air volume of the cyclone dust collector, m3/h; A—the inlet cross-sectional area of the cyclone dust collector, m2. Therefore, when the structure is fixed (R is unchanged, A is unchanged), and the dust is the same (m is stable), the airflow velocity of the dust collector population is proportional to the inlet air volume, and the inlet air volume of the cyclone dust collector is caused by the inlet of the induced draft fan The air volume is determined.

We produce 2 stage cyclone dust collector.If you are looking for the 2 stage cyclone dust collector,pls contact with us.

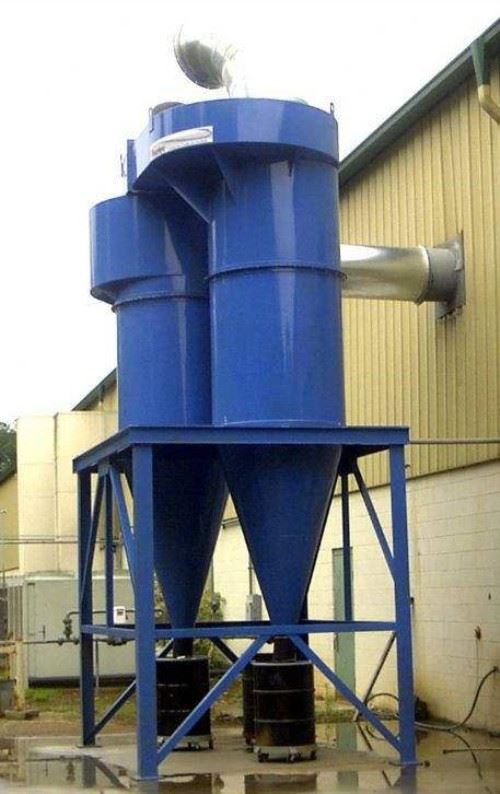

Dust collectors can be divided into two categories: ① Dry dust collectors: including gravity sedimentation chambers, inertial dust collectors, electric dust collectors, bag dust collectors, cyclones dust collectors. ②Wet dust collector: including spray tower, impact dust collector, venturi detergent, foam dust collector and water film dust collector. At present, the most common applications are cyclone separators, electrostatic precipitators and bag filters.

Advantages of dry dust collectors: wide range of use, most dust removal objects can use dry dust collectors, especially for large-scale centralized dust removal systems; the state of dust discharge is dry powder, which is conducive to centralized treatment and comprehensive utilization.

The disadvantages of dry dust collectors are: they cannot remove toxic and harmful components in the gas; improper handling can easily cause secondary dust.