Description

Air back-blown bag filter is developed by condensing the advantages of various bag dust collectors at home and abroad. It is a new type of dust removal device that combines the cyclone dust removal mechanism and the filter dust removal mechanism.

Share:

Air back-blown bag filter is developed by condensing the advantages of various bag dust collectors at home and abroad. It is a new type of dust removal device that combines the cyclone dust removal mechanism and the filter dust removal mechanism.

Working principle

After the dust-containing airflow enters the dust collector tangentially, the cyclone body first separates the large particles of dust into the ash hopper, which plays the role of primary dust removal. The fine dust particles are suspended in the gas and passed through the airflow distribution device, evenly entering the filter room and dispersed in the filter The gap between the bags is blocked by the filter bag, and the purified air flow is discharged by the main fan.

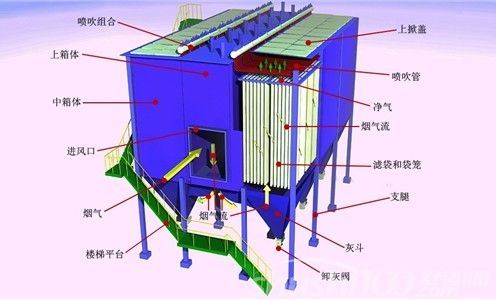

The structure of air back-blown bag filter

1. According to the shape of the filter bag, it is divided into: flat bag (trapezoid and flat plate) and round bag (cylindrical).

2. According to the way of inlet and outlet, it can be divided into: downward inlet and upper outlet, upper inlet and lower outlet, and direct current type (only for flat flat bags).

3. According to the filtering method of the bag, it is divided into: external filtering type and internal filtering type. Fibers for filter materials include cotton fibers, wool fibers, synthetic fibers, and glass fibers. The filter materials woven by different fibers have different properties. Commonly used filter materials are 208 or 901 polyester velvet cloth, the use temperature is generally not more than 120 ℃, the use temperature of the glass fiber filter bag treated with silicone resin is generally not more than 250 ℃, cotton wool fabric is generally suitable for non-corrosive; Dust-containing gas below 80-90 ℃.

Characteristics of air back-blown bag filter

1. High dust removal efficiency, it can collect fine dust with a particle size greater than 0.3 microns, and the dust removal efficiency can reach more than 99%.

2. Flexible use, the air volume can be hundreds of cubic meters per hour in the room, small square meters near the machine tool to hundreds of thousands of cubic meters per hour, directly set as a unit, can also be used as a large dust removal room, namely "bag room ".

3. The bag-type dust collector has a simple structure, stable operation, less initial investment (compared to the electric dust collector), and easy maintenance. Therefore, bag dust collectors are widely used to eliminate dust pollution, improve the environment, and recycle materials.

4. The key filter material of the bag dust collector is now more than 2 years in service life, and has achieved 4-6 years of actual performance.

5. In dry and semi-dry desulfurization systems, it can further reduce the SO2 contained in the flue gas.