Description

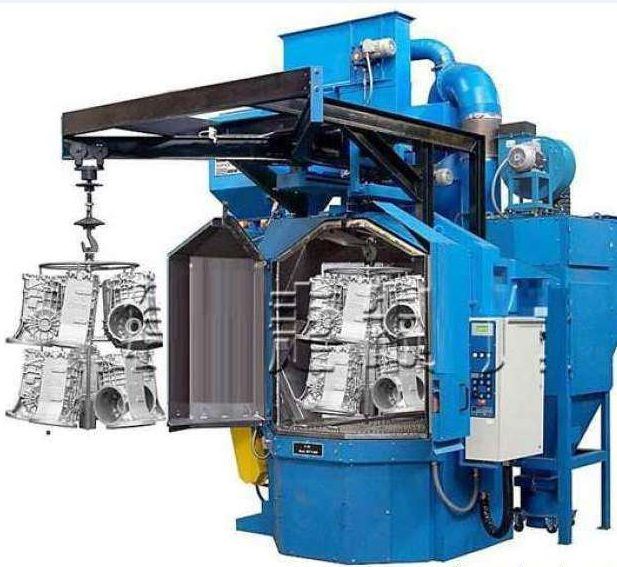

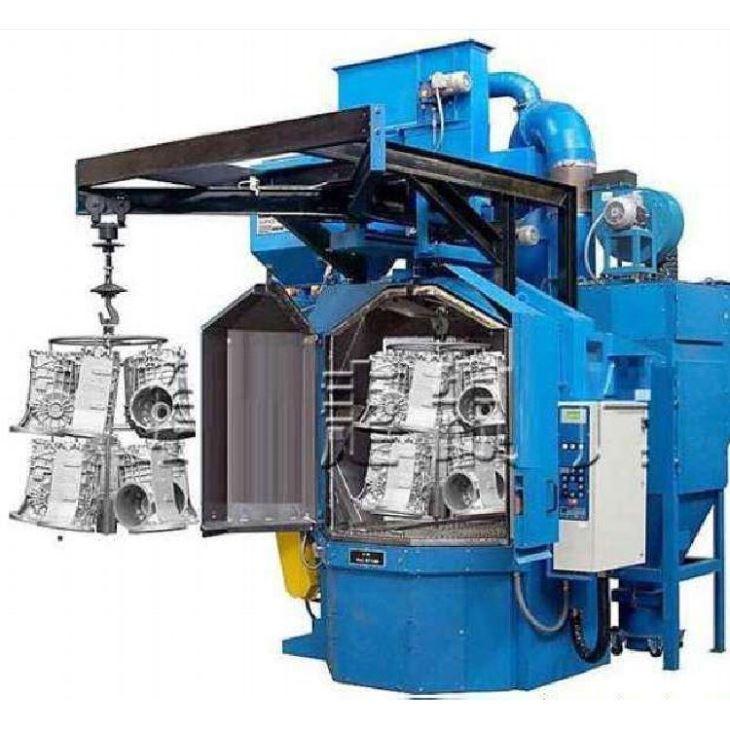

The double hook shot blasting machine is loaded with two hooks to load the workpiece alternately into the shot blasting cleaning room, and the shot blaster is used to throw the projectile toward the surface of the workpiece, so that the surface of the workpiece reaches a certain roughness, making the workpiece beautiful, or changing the workpiece compressive stress increases life.

Share:

The double hook shot blasting machine is loaded with two hooks to load the workpiece alternately into the shot blasting cleaning room, and the shot blaster is used to throw the projectile toward the surface of the workpiece, so that the surface of the workpiece reaches a certain roughness, making the workpiece beautiful, or changing the workpiece compressive stress increases life.

The double hook shot blasting machine is used in the surface cleaning or strengthening treatment of small and medium-sized castings and forgings in casting , construction, chemical, motor, machine tool and other industries widely. And The double hook shot blasting machine is suitable for the cleaning of slender and thin-walled parts that are not suitable for collision. The hook type shot blasting machine is the standard model of the shot blasting machine. Its working cylinder diameter is from 900 to 1300 mm, and the height is from 1300 to 2200 mm. The standard model is equipped with 2-7 throwing heads and the maximum load capacity is up to 10000 kg. The production efficiency of the double hook shot blasting machine is quite high and the flexibility span is also quite large. It is an ideal cleaning and strengthening equipment, and it is easy to operate. Load the workpiece to be processed on the machine, press the start button, and after a short time (usually 5-7 minutes), the entire cleaning process is completed, all dust and residual pellets are removed, which is mainly suitable for various kinds of , Surface treatment of large castings, forgings, weldments, heat-treated parts, including fragile and irregularly shaped workpieces.