The powermatic dust collector is divided into the following three categories according to its principle of action (1) Filter type dust collector, including bag dust collector and particle layer dust collector, etc. (2) Electrostatic precipitator. (3) Magnetic dust collector....

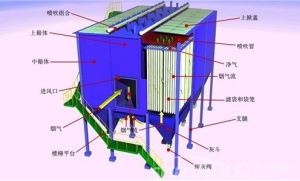

Industrial bag filter is a filter type dust removal device based on the filtering principle, which uses organic fiber or inorganic fiber filter cloth to filter the dust in the gas.

According to foreign experience, there are three different levels of dust removal equipment: the first choice is dust, that is, like various diseases, prevention is always more cost-effective than treatment, such as loading and unloading, adding a flow slot during belt...

Pulse cartridge dust collector is mainly used in the following occasions: chemical industry, medicine, steel plant, power plant, carbon, abrasive, wood, smelting.

There are many points to be aware of when using the dust catcher: Prevent the dust removal efficiency from decreasing It is necessary to prevent the gas from cooling below the dew point in the bag dust catcher during use, especially when using the bag dust catcher under...

Shop dust collector refers to the use of corresponding dust removal equipment to effectively solve the workshop environmental problems, giving workshop workers a warm and comfortable working environment, the purpose is to improve work efficiency, protect the environment, and...

Dust extraction system can be divided into two types: commercial type and household type from the perspective of use. From the operation, dust extraction system can be divided into two types: centralized management type and household management type. From the development of...

Shop dust collector refers to the use of corresponding dust removal equipment to effectively solve the workshop environmental problems, giving workshop workers a warm and comfortable working environment, the purpose is to improve work efficiency, protect the environment, and...

Pulse cartridge dust collector is mainly used in the following occasions: chemical industry, medicine, steel plant, power plant, carbon, abrasive, wood, smelting.

According to foreign experience, there are three different levels of dust removal equipment: the first choice is dust, that is, like various diseases, prevention is always more cost-effective than treatment, such as loading and unloading, adding a flow slot during belt...

Air back-blown bag filter is developed by condensing the advantages of various bag dust collectors at home and abroad. It is a new type of dust removal device that combines the cyclone dust removal mechanism and the filter dust removal mechanism.

There are many points to be aware of when using the dust catcher: Prevent the dust removal efficiency from decreasing It is necessary to prevent the gas from cooling below the dew point in the bag dust catcher during use, especially when using the bag dust catcher under...

Sep 01, 2020

Aug 31, 2020