In some processing workshops, there are a large amount of fine metal particles suspended in the air that are harmful to humans. As China's environmental protection authorities have become more and more strict with the green production indicators of enterprises, and have...

Bin top filter cylinder dust collector is the same as the normal filter cartridge dust collector in production, except that the bottom uses a flange chain to receive the basket. It is a relatively simple filter cartridge dust removal equipment.

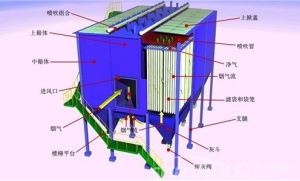

Since its advent in the 1950s, the pulsed bag filter has been widely used at home and abroad, and has been continuously improved.

Industrial bag filter is a filter type dust removal device based on the filtering principle, which uses organic fiber or inorganic fiber filter cloth to filter the dust in the gas.

Air back-blown bag filter is developed by condensing the advantages of various bag dust collectors at home and abroad. It is a new type of dust removal device that combines the cyclone dust removal mechanism and the filter dust removal mechanism.

The pressure loss of bag-type dust removal refers to the pressure drop of gas from the dust collector inlet to the outlet, or resistance. The pressure loss of bag dust removal depends on the following three factors: ⑴ Pressure loss of equipment structure. ⑵ Pressure loss of...

The smaller the particle size of vortex dust collector, the higher the dust removal efficiency of the dust collector. The size of the centrifugal force is related to the dust particles. The larger the particle, the greater the centrifugal force. When the particle size and...

Baghouse dust collector can efficiently remove dry dust and smoke dust, the removal rate can reach 99%, and can be widely used in the dust collection of cement, power, metallurgy, chemical industry and other waste gas, such as cement mill, raw mill, mine crushing, materials...

That is, the inlet dust concentration is determined by the process of the dust point. When designing or selecting a bag-type dust collector, it is another important factor second only to the air volume. Expressed in g/m or g/Nm. For bag industrial dust collection system, the...

Generally speaking, the collection port according to different working conditions and dust types are generally: the equipment comes with a dust removal excuse, suction arm, suction hood port, etc. The conveying part is generally selected according to the wind speed and...

The pressure loss of bag-type dust removal refers to the pressure drop of gas from the dust collector inlet to the outlet, or resistance. The pressure loss of bag dust removal depends on the following three factors: ⑴ Pressure loss of equipment structure. ⑵ Pressure loss of...

Because cement will produce a lot of solid particulate dust during production, storage and transportation, it not only affects the image, but also affects health.

Sep 01, 2020

Aug 31, 2020