Since its advent in the 1950s, the pulsed bag filter has been widely used at home and abroad, and has been continuously improved.

Dust extraction is technical measures to remove particulate matter from dusty gases to reduce their emissions to the atmosphere. Dust-containing industrial waste gas may be generated from mechanical processes such as crushing, screening, transportation, and blasting of solid...

In some processing workshops, there are a large amount of fine metal particles suspended in the air that are harmful to humans. As China's environmental protection authorities have become more and more strict with the green production indicators of enterprises, and have...

There are many points to be aware of when using the dust catcher: Prevent the dust removal efficiency from decreasing It is necessary to prevent the gas from cooling below the dew point in the bag dust catcher during use, especially when using the bag dust catcher under...

That is, the inlet dust concentration is determined by the process of the dust point. When designing or selecting a bag-type dust collector, it is another important factor second only to the air volume. Expressed in g/m or g/Nm. For bag industrial dust collection system, the...

The cyclone dust extractor uses centrifugal force to remove dust. The greater the centrifugal force, the better the dust removal effect. In the circular motion (or curve motion), the centrifugal force on the dust is F=ma, where F--centrifugal force, N; m--dust mass, kg;...

Because cement will produce a lot of solid particulate dust during production, storage and transportation, it not only affects the image, but also affects health.

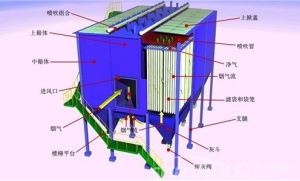

Air back-blown bag filter is developed by condensing the advantages of various bag dust collectors at home and abroad. It is a new type of dust removal device that combines the cyclone dust removal mechanism and the filter dust removal mechanism.

There are many points to be aware of when using the dust catcher: Prevent the dust removal efficiency from decreasing It is necessary to prevent the gas from cooling below the dew point in the bag dust catcher during use, especially when using the bag dust catcher under...

Because cement will produce a lot of solid particulate dust during production, storage and transportation, it not only affects the image, but also affects health.

Pulse cartridge dust collector is mainly used in the following occasions: chemical industry, medicine, steel plant, power plant, carbon, abrasive, wood, smelting.

The pressure loss of bag-type dust removal refers to the pressure drop of gas from the dust collector inlet to the outlet, or resistance. The pressure loss of bag dust removal depends on the following three factors: ⑴ Pressure loss of equipment structure. ⑵ Pressure loss of...

Sep 01, 2020

Aug 31, 2020