21

Feb

Working principle of axle shot blasting machine

Working principle of axle shot blasting machine

The round rod and tube shot blasting machine can work continuously and uninterruptedly. It can deoxidize, clean and pretreat various steel materials, such as steel pipes, round rods, shafts, etc. in a continuous way. The operation is simple, just load the steel material on the machine, press the...

19

Feb

Working principle of catenary shot blasting machine

Working principle of catenary shot blasting machine

When the catenary shot blasting machine is in the shot blasting operation, the button is cut into the automatic program, the shot recovery system and the dust recovery system are started, the workpiece is brought into the shot blasting room by the accumulation chain system, and the first group...

17

Feb

Working principle of axle-through shot blasting machine

Working principle of axle-through shot blasting machine

The round rod and tube shot blasting machine can work continuously and uninterruptedly. It can deoxidize, clean and pretreat various steel materials, such as steel pipes, round rods, shafts, etc. in a continuous way. The operation is simple, just load the steel material on the machine, press the...

16

Feb

Outstanding advantages of axle-through shot blasting machine

Outstanding advantages of axle-through shot blasting machine

1. Adopt high chromium guard plate + full manganese steel guard plate double-layer guard plate protection, the service life is 20 years; 2. Adopt V-wheel system for transmission, frequency conversion speed regulation; 3. Adopt the two-stage separation system of broken pellets; 4. Use...

14

Feb

The Hook Type Shot Blasting Machine

The Hook Type Shot Blasting Machine

There are many types of shot blasting machines, but today we will introduce one of them specifically, which is the hook type shot blasting machine. Trial run of 1 hook shot blasting machine (1) Check all parts of the machine to see if they are firmly connected, and lubricate the equipment as...

13

Feb

Do you know the trial run and dry run of the hook shot blasting machine?

Do you know the trial run and dry run of the hook shot blasting machine?

1.Features of hook shot blasting machine: It adopts double hook hanging form, one outside and one inside. When the workpiece is hung by the hook in the cleaning room for shot blasting, the external hook can manually unload the cleaned workpiece and hang the workpiece to be cleaned. When the...

12

Feb

Daily maintenance of road shot blasting machine

Daily maintenance of road shot blasting machine

1.Conventional lubrication: The motor and transmission parts of the electric actuator of the shot blasting machine need to use lubricating oil, and the viscosity of the oil changes with the oil temperature. If the viscosity is too low, the wear of gears and other transmission parts will...

11

Feb

Overview of shot blasting technology

Overview of shot blasting technology

Shot blasting (sand) technology is divided into shot blasting and shot blasting (sand) technology. There are also some industries called sand blasting, sand blowing, bead blasting, blasting, etc. It was first used for casting and forging parts such as sticky sand and oxide skin. Remove. Shot...

10

Feb

Application range of shot blasting technology

Application range of shot blasting technology

Metal surface cleaning Surface cleaning of various castings Shot blasting equipment is first applied to the removal of sand and oxide scale on the surface of cast steel and iron castings in the foundry industry. Almost all steel castings, gray castings, malleable steel parts, ductile iron parts,...

09

Feb

Analysis of application of shot blasting and shot peening technology

Analysis of application of shot blasting and shot peening technology

The application of shot blasting technology can effectively improve and enhance the fatigue life and corrosion resistance of key automotive components. At present, many well-known automobile manufacturers and component manufacturers in the world have included strengthening in the standard...

08

Feb

How to operate and maintain the through shot blasting machine?

How to operate and maintain the through shot blasting machine?

1.The pass-through shot blasting machine is a kind of shot blasting machine for us, but it is different from other cleaning machines, so it needs to be explained and understood, but in general, it is still a shot blasting machine equipment, and Different from shot blasting equipment, let's...

07

Feb

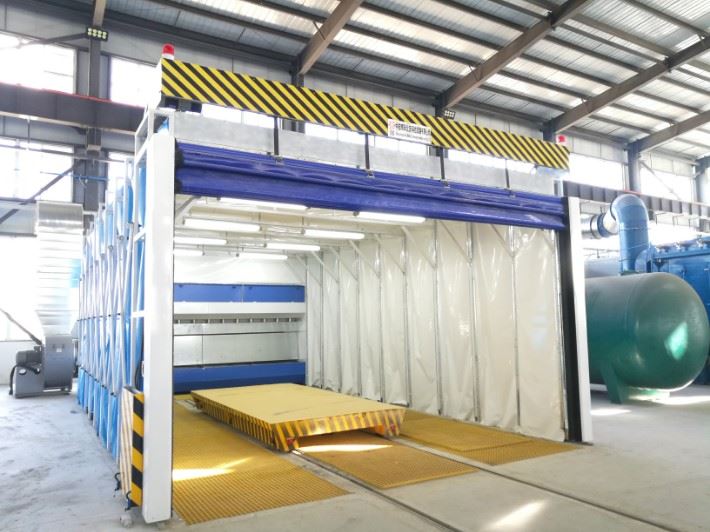

Design skills of sandblasting room for painting equipment

Design skills of sandblasting room for painting equipment

The main function of the sandblasting room is to perform sandblasting operations. The use of the sandblasting room can bring a lot of convenience to people's work and can greatly improve people's work efficiency. The design of the sandblasting room is very ingenious. The work performance...

06

Feb

Matters needing attention when spraying the dust removal system of the sandblasting room

Matters needing attention when spraying the dust removal system of the sandblasting room

The spraying room is generally equipped with a dust removal system, because the spraying room will generate a lot of dust during the work process, so you must install a dust removal system to deal with the dust in time. However, workers must master when spraying The right way is to minimize...

05

Feb

What are the working environment requirements of the blast room dust removal system

What are the working environment requirements of the blast room dust removal system

Generally, dust removal systems are installed in rooms to ensure a clean indoor environment. Most of the dust removal systems are installed in some production workshops, because the products produced in this way will be cleaner. Now many sandblasting rooms also install dust removal systems, but...

04

Feb

The difference between shot blasting machine and sandblasting machine

The difference between shot blasting machine and sandblasting machine

Sandblasting machine and shot blasting machine are two different surface rust removal and surface roughening equipment. The difference between the two: 1. Sand blasting uses compressed air as the power, and the compressed air carries sand (emery, corundum, etc.) to impact the surface of the...

03

Feb

Application scope and characteristics of the composition system of dry and wet sandblasting room

Application scope and characteristics of the composition system of dry and wet sandblasting room

Features of dry and wet sandblasting room: 1. Environmentally friendly pneumatic recycling sandblasting room, no need for deep pits (or not for pits), low infrastructure costs, and short construction period; 2. Equipped with abrasive separation and sorting device, the abrasive is automatically...

02

Feb

Five different ways to treat waste gas from sandblasting rooms

Five different ways to treat waste gas from sandblasting rooms

There are many ways to deal with waste gas from sandblasting rooms. Here are five different ways to treat waste gas from sandblasting rooms. Water spray: This method is widely used in air pollution treatment. In addition, the spray method is also used in the spraying process. Its principle is to...

01

Feb

Precautions for choosing a sandblasting room

Precautions for choosing a sandblasting room

The economic development is getting faster and faster, and sometimes a simple small machine can't meet the production needs of a large company, so at this time you need to use a large sandblasting room. Obviously, a large machine like a sandblasting room , You must carefully understand all...

31

Jan

Composition system and application field of sandblasting room Component system and application fi...

Composition system and application field of sandblasting room Component system and application fi...

The structure of the sandblasting room includes a working room, abrasive recycling system, workpiece conveying system, lighting system, etc. The main reason for using the sandblasting room is that its construction time is relatively short, the required cost is relatively low, and there will be...

30

Jan

What are the characteristics and applications of crawler shot blasting machine and sandblasting m...

What are the characteristics and applications of crawler shot blasting machine and sandblasting m...

Crawler sandblasting machine has very high working efficiency, so many people like to use this sandblasting machine very much. This sandblasting machine can save a lot of energy consumption during work, and it saves a lot of use cost invisibly, and it is very simple to operate, and the operator...